- +39 051 664 0945

- info@trm.it

- Mon - Fri: 08:30-12:30 / 13:30-17:30

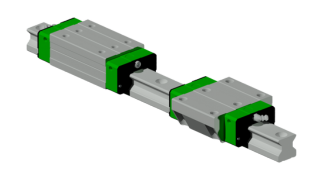

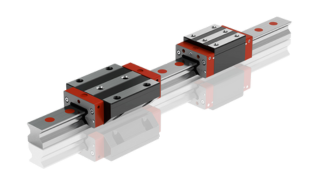

Linear roller-recirculating guides

Roller recirculating guides are high performance, high precision components for applications with important stresses and loads.

High rigidity, large static and dynamic load capacity, maximum travel smoothness are the main characteristics of our roller guides. The high stiffness allows to improve the performance of the machines on which they are applied, reducing positioning errors, decreasing vibrations and increasing the service life of other wearing parts.